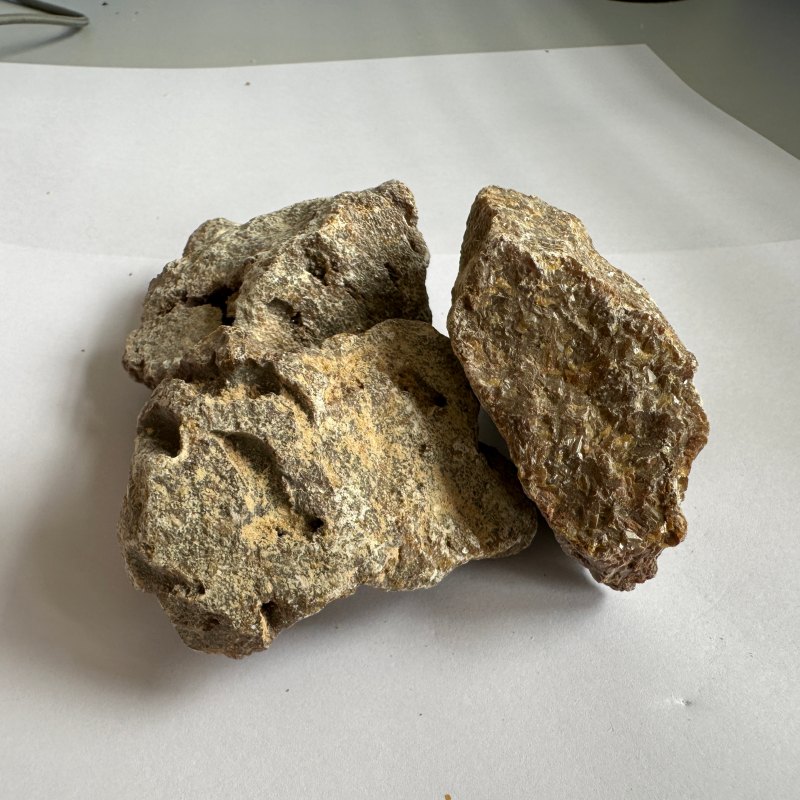

Taljeni magnezij za ognjevzdržne opeke

1,97 taljeni magnezij se pogosto uporablja pri proizvodnji magnezijevih ogljikovih opek

2. Močna odpornost proti koroziji: Taljeni magnezij kaže močno odpornost proti koroziji iz staljenih kovin in žlindre, zaradi česar je idealen material za oblaganje peči in lončkov.

3. Dobra električna izolacija: Električni taljeni magnezijev pesek ima dobre električne izolacijske lastnosti, zaradi česar je primeren za uporabo v električnih izolacijskih aplikacijah.

- QianHe Refractories

- Haicheng, Liaoning, Kitajska

- v roku 30 dni

- 300000 ton na leto

- informacije

Običajni taljeni magnezij | ||||||||

| SPEC | LOI % ≤ | SiO % ≤ | CaoO % ≤ | Fe2O3%≤ | AL2O3%≤ | MgO % ≥ | BD (g/cm)≥ | VELIKOST |

| (MM) | ||||||||

| 98 | 0,1 | 0,6 | 0,8 | 0,5 | 0,1 | 98 | 3.5 | 0-150 |

| 97.5 | 0,12 | 0,8 | 1 | 0,6 | 0,12 | 97.5 | 3.5 | 0-150 |

| 97 | 0,15 | 1 | 1.2 | 0,7 | 0,15 | 97 | 3.5 | 0-150 |

| 96 | 0,2 | 1.5 | 1.5 | 0,9 | 0,2 | 96 | 3.45 | 0-150 |

1.Značilnosti taljenega magnezija

Električni fuzijski magnezij ima odlične lastnosti, zaradi katerih je zelo zaželen v panogah, kot so vesoljska, avtomobilska, elektronika in gradbeništvo. Ima nizko gostoto, visoko razmerje med trdnostjo in težo ter dobro odpornost proti koroziji, zaradi česar je idealen material za lahke strukturne komponente. Poleg tega ima dobro toplotno in električno prevodnost, zaradi česar je primeren za uporabo v hladilnikih, električnih konektorjih in drugih elektronskih komponentah.

2.Značilnosti taljenega magnezija

električni fuzijski magnezij je mogoče enostavno obdelovati, variti in oblikovati, kar omogoča vsestransko uporabo v različnih panogah. Zaradi svoje edinstvene kombinacije lastnosti je prednostna izbira pri proizvodnji komponent letal, avtomobilskih delov, potrošniške elektronike in raznih drugih izdelkov.

QianHe Refractories v mestu Haicheng v provinci LiaoNing,

kjer slovi po težkem in bogatem rudniku magnezita na svetu.

Izdelujemo izdelke iz magnezijevega oksida, vključno s taljenim magnezijevim oksidom, magnezijevim oksidom,

2:1 low silicon high calcium fused magnesia ,arge crystal of fused magnesia

and DBM90,DBM92,DBM97.

The production process of fire-resistant material electric fused magnesia products typically involves the following steps:

1. Raw material preparation: The first step is to obtain high-quality magnesite ore. The ore is then crushed, ground, and screened to ensure consistent particle size and purity.

2. Calcination: The crushed magnesite is then heated in a rotary kiln or a shaft kiln at high temperatures (around 1500°C) to remove impurities and convert it into magnesia clinker.

3. Briquetting: The magnesia clinker is mixed with a binder and pressed into briquettes or pellets of the desired shape and size. This process improves the density and strength of the final product.

4. Electric melting: The briquettes or pellets are then placed in an electric arc furnace. The furnace is heated to extremely high temperatures (above 2800°C) using electric current. This intense heat causes the magnesia to melt and form a liquid.

5. Cooling and solidification: Once the magnesia has melted, it is allowed to cool and solidify. This process may involve controlled cooling rates to achieve desired crystal structures and minimize defects.

6. Crushing and grading: The solidified magnesia is crushed into smaller particles and then graded according to particle size. This ensures uniformity and consistency in the final product.

Packaging and storage: The final product is packaged in suitable containers or bags for storage and transportation. Proper labeling and documentation are also important for quality control and traceability.

Throughout the production process, quality control measures are implemented to ensure that the final product meets the required specifications and performance standards. These may include chemical analysis, physical property testing, and visual inspection.